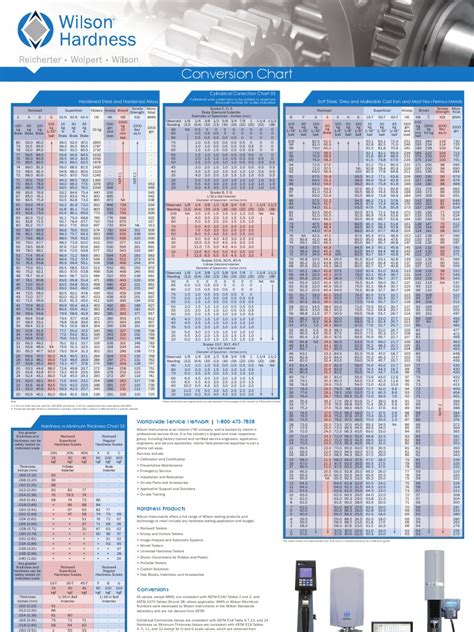

hardness test hrb chart|hardness to strength conversion chart : companies 76.9. These corrections are approximate only and represent the averages to the nearest 1/2 Rockwell number. 1: A 10 mm steel ball was used for 450 BHN and below. A 10 mm carbide .

13 de dez. de 2023 · 51K views 1 month ago #LegoFortnite #FortniteLego #Fortnite. This is a guide video on what the charms and equipment are to use in the LEGO Fortnite .

{plog:ftitle_list}

WEBSeja um Franqueado. Área Cliente. Comprar ou alugar imóveis é na Apolar. Encontre tudo sobre o mercado imobiliário aqui! Entre em contato pelo nosso site, ligue ou visite uma .

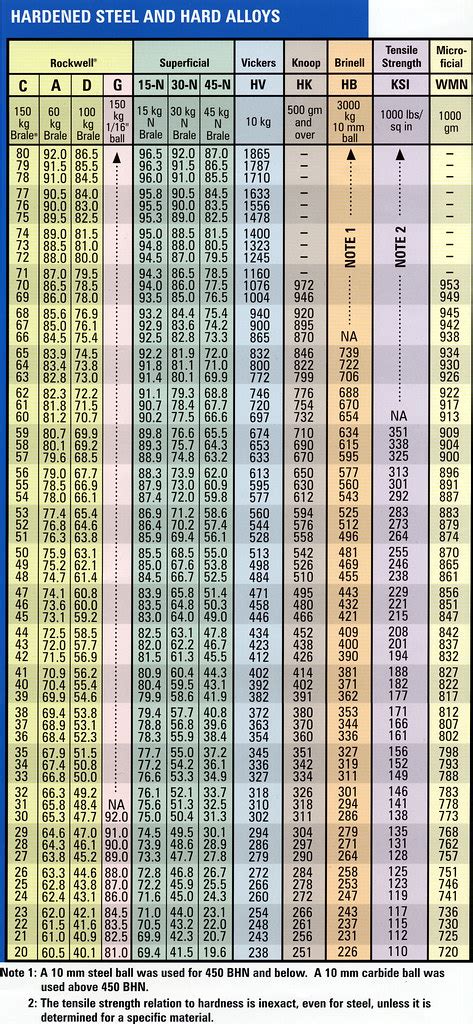

The most common is the static load indentation hardness test, such as Brinell Hardness (HB), Rockwell Hardness (HRA, HRB, HRC), and Vickers Hardness (HV). These hardness values indicate the ability of a . This table shows approximate hardness of steel using Brinell, Rockwell B and C and .

Simply input the hardness value, select the source and target scales, and receive instant hardness conversion results. Instantly convert Hardess values between HRB, HB, HRC, and HV. Steel Hardness . Brinell and Rockwell Hardness Conversion Chart - These Conversion Tables .Rockwell B to C Hardness Conversion Chart. In this blog post, you’ll read:While the Rockwell hardness testing scale is prevalent, it is best to consider the material thickness and softness .

76.9. These corrections are approximate only and represent the averages to the nearest 1/2 Rockwell number. 1: A 10 mm steel ball was used for 450 BHN and below. A 10 mm carbide .This chart shows you the approximate hardness conversion numbers for non-austenitic steels. Convert Brinell (HBW), Rockwell (HRC), Vickers (HV), and Knoop (HK) hardness and steel .HARDNESS CONVERSION CHART HRA HRB HRC HRD HRE HRF 15-N 30-N 45-N 30-T 3000 kg 500 kg Rockwell Rockwell Superficial Brinell Vickers Shore 61 98 21 40.9 --- --- 69.9 42.3 .

There are seven separate scales under the Rockwell umbrella, letters A-G, but the most common scales used on steel are B and C, often abbreviated HRB and HRC respectively. The B scale . HV, HB, HRC Hardness Comparison Chart. Hardness testing is the simplest and most straightforward method among mechanical property tests. In order to replace certain mechanical property tests with hardness tests, a .This chart shows you the approximate hardness conversion numbers for non-austenitic steels. Convert Brinell (HBW), Rockwell (HRC), Vickers (HV), and Knoop (HK) hardness and steel tensile strength. . (HRB range) HK (HRC range) HK (HRB range) Scroll down to view full table: 2.45. 627. 58.6-664-703-346.2. 2.50. 601. 57.3-638-677-328.9. 2.55. 578 .

The Rockwell hardness test is often used as a ‘quick test’ on the production floor or in the laboratory, mainly for metallic materials. . HRB, HRC, HR30N). Definition of the Rockwell hardness test method The Rockwell hardness test .

wilson hardness conversion chart

For example, anodizing can significantly increase the hardness and wear resistance of aluminum alloys. Aluminum Alloy Hardness Chart. The table below provides typical Vickers hardness values measured with a Tianxing W-20 Vickers hardness tester for nearly 400 different grades of aluminum alloy materials with different heat treatment processes.Hardness Conversion Formula. Y = aX^2 + bX + c. Where: Y is the hardness value in the target scale; X is the hardness value in the original scale; a, b, and c are constants determined through empirical testing; Example: Converting Brinell (HB) to Rockwell C (HRC) for steels:. HRC = -0.000000567 HB^2 + 0.0624 HB – 13.7. Using this formula, we can convert a Brinell hardness .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.Rockwell B HRB (1/16" ball 100 kg) Leeb HLD [1] 800-72-856 780: 1220: 71-850 760: 1210: 70 . "Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb Hardness" (2019) . Rockwell to Brinell conversion chart .

Rockwell Hardness (HRC and HRB) and Brinell Hardness (HB or BHN) are most commonly used for steel and iron castings. Although there is no accurate conversion tables and equations, but dandong foundry recommend the following formulas and comparison tables according to the experience and standards.Numbers in parentheses indicate hardness values, which are outside the definition area of the standard hardness test, but often used as approximate values. The Brinell values in parenthesis are only used when measured with a hard metal ball. 1) Calculated as: HB = 0.95 x HV . 2 HRB C A HARDNESS CONVERSION TABLE

The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness

The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting Rockwell hardness numbers to a different scale like Brinell or Vickers.. The hardness data can not be presented in terms of a universal conversion .Hardness Tester Conversion Charts , Hardness Tester Scale Conversions, rockwell hardness conversions, brinell conversions, vickers conversions . Rockwell B 100kgf (HRB) Vickers (HV) 10-mm Standard ball 3000kgf (HBS) Knoop 500-gf and Over (HK) . Corrections to be added to test results in the following scales for various diameter parts.Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and . The corrections vary according to the sample's diameter and hardness and can be as much as six points on the HRC scale and 12.5 points on the HRB scale. The HRC and HRB scales are the most popular Rockwell scales used. HRC uses a diamond indenter with a 150-KG test force and is used mainly for hardened steels.

Hardness test methods and hardness conversion tables Introduction. Hardness is a surface property where indentation, scratching or wear is resisted. The higher the hardness the more resistant is the surface, and the more difficult surface operations such as cutting and machining are. . Vickers Hardness (HV) Rockwell (HRB) Rockwell (HRC) UTS .Converting hardness Rockwell B (HRB) to hardness Rockwell C (HRC) is a usual practice for many designers when specifying the hardness value of a material. This conversion is possible using charts and tables calculated using formulas to get approximate but acceptable values that can be interchanged for the different Rockwell hardness testing scales. Stainless Steel Hardness Test Method Brinell hardness. The Brinell hardness test is a commonly used hardness assessment method suitable for softer materials. It calculates the hardness by the size of the indentation left by a steel ball when it is pressed into the material. It is expressed in HB, and the larger the value, the harder the material. Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter.. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is .

The hardness of steel depends on several factors, such as its composition, manufacturing, and heat-treating processes.The different hardness scales use different loads, different indentor shapes, and different measurements to obtain the hardness number. There are no straightforward formulae to establish relationships between the different scales, making .Luckily, you do not have to remember all of them because we’ll show you a simple HRB to Vickers hardness conversion chart. Keep reading and learn more about each unit of measure. . Vickers hardness test is an automated hardness testing method used to determine the resistance of materials to indentation. The procedure involves applying a .

%PDF-1.4 %âãÏÓ 5456 0 obj > endobj xref 5456 26 0000000016 00000 n 0000001299 00000 n 0000001459 00000 n 0000003708 00000 n 0000004153 00000 n 0000004588 00000 n 0000011237 00000 n 0000014994 00000 n 0000018082 00000 n 0000022060 00000 n 0000025218 00000 n 0000028630 00000 n 0000032318 00000 n 0000035348 00000 n .Conversion table/chart for Brinnel and Rockwell hardness scales and tensile strengths. Buy metals and plastics online in small quantities, cut to order. . The table below converts Brinell Hardness to Rockwell Hardness scales and vice versa, then compares those to the approximate tensile strength that those scales indicate. . FREE Mill Test . Related reading: Hardness Conversion Chart: HLD, HRC, HRB, HV, HB, HSD Whether you’re a seasoned professional looking to refine your material selection process or an engineer just starting out in the industry, this information serves as a valuable resource for enhancing your understanding of copper alloy properties.Rockwell: Rockwell Superficial: Brinell: Vickers. Shore : A: B: C: D: E: F: 15-N: 30-N: 45-N: 30-T: 3000 kg: 500 kg: 136 . Approx Tensile Strength (psi) 60kg Brale .

In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the Rockwell C scale. The higher the number on the RC scale, the harder the steel is. Conversely, the lower the RC scale number is, the softer the steel. . Rockwell Hardness Test Part 1 – Test Method (ISO 6508-1 Metallic Materials)Hardness conversion tables for Rockwell, Brinell, Vickers. Hardness Testers. Durometers; Thickness Gauges EMAT; Leeb Rebound Hardness Tester | CIMETRIX Ltd

Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). . HRB, HRC, etc., .

tensile strength vs hardness chart

WEB1 de fev. de 2024 · By a piquant irony, Abigail Morris now finds herself at the receiving end of accusations about systemic inequality. This time the claims relate to class. She and her Last Dinner Party bandmates.

hardness test hrb chart|hardness to strength conversion chart